The nature of materials used in the domain of development and manufacturing can have a significant impact on the outcome of a task. Cold-finished bars, otherwise called cold-drawn bars, are a perfect representation of how exceptional material processing can enhance both precision and performance. For Cold finished bar Long Island, where exclusive expectations and strength are vital, cold-finished bars offer a few benefits that can raise the general quality and effectiveness of development.

What Are Cold-Finished Bars?

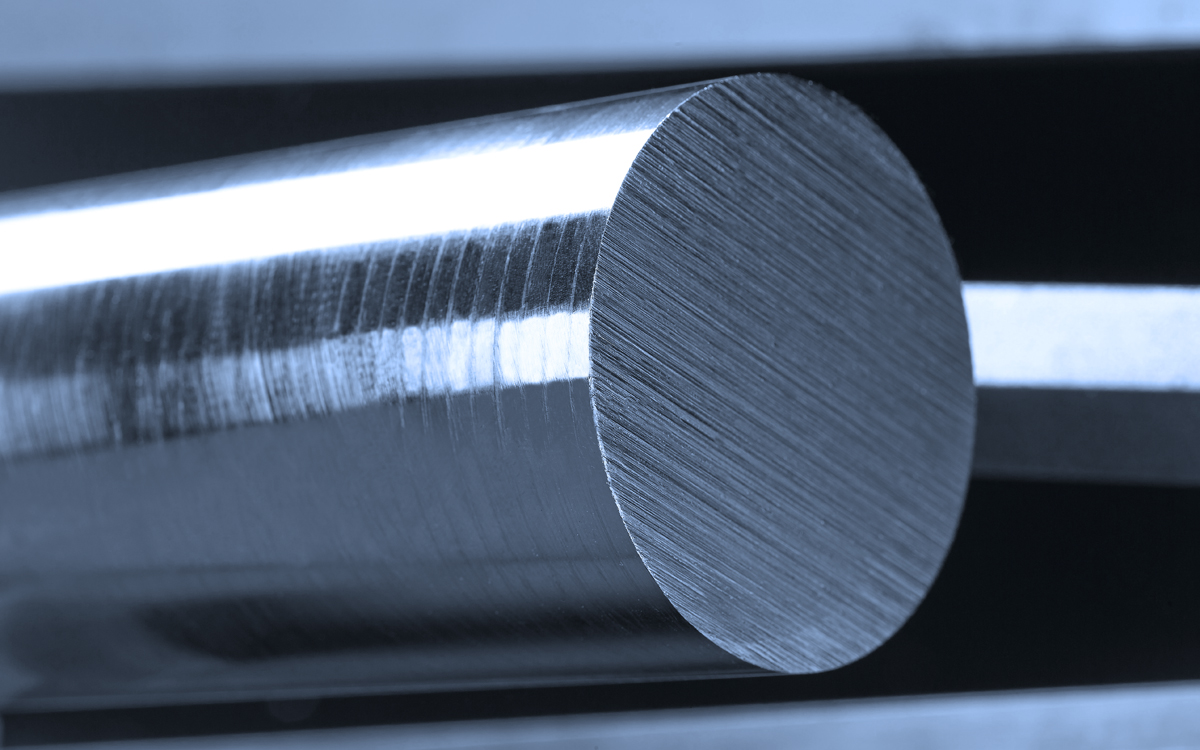

Cold-finished bars are steel bars that go through a particular cycle to work on their properties. Not at all like hot-moved bars, which are handled at high temperatures, cold-finished bars are exposed to a progression of tasks at room temperature. These cycles commonly include drawing, grinding, and polishing, which refine the bar’s surface and layered exactness.

Enhanced Precision

One of the vital advantages of cold-finished bars is their outstanding precision. The cold drawing process lessens the bar’s measurement to extremely close resiliences, ensuring predictable aspects across all bars. This precision is urgent for projects requiring definite estimations, like in the development of machinery, primary parts, and intricate structural components.

Worked on Mechanical Performance

Cold-finished bars show better mechanical properties thought about than their hot-moved partners. The cold drawing process increases the bar’s elasticity and hardness, making it more impervious to wear and twisting. This improvement in mechanical performance is fundamental for applications subject to high pressure and burden, for example, reinforcing bars in substantial designs or parts in large equipment.

Enhanced Surface Quality

The surface Cold finished bar Long Islandis another region where they succeed. The cold drawing process brings about a smooth, clean surface liberated from scale and different defects. This great finish isn’t just tastefully pleasing yet in addition helpful for applications where surface quality effects performance, for example, in precision engineering and cutting-edge manufacturing.

Applications in Long Island Projects

Cold finished bars are flexible and can be utilized in a great many applications. In Long Island development projects, they are frequently utilized in primary steelwork, reinforcement, and mechanical parts. Their precision, strength, and surface quality make them ideal for both private and business projects where quality and performance are fundamental.

Cold-finished bars assume an imperative role in enhancing precision and performance in development and manufacturing projects. Their capacity to give careful aspects, predominant mechanical properties, and an amazing surface finish makes them an invaluable material for top-notch projects on Long Island. By choosing cold finished bars, workers for hire and producers can guarantee that their projects satisfy the most elevated guidelines of strength, usefulness, and tasteful allure.